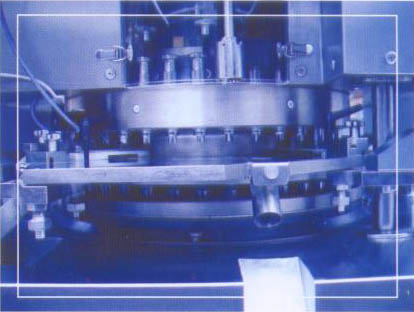

Vanguard introduces our new double sided high speed rotary tablet presses

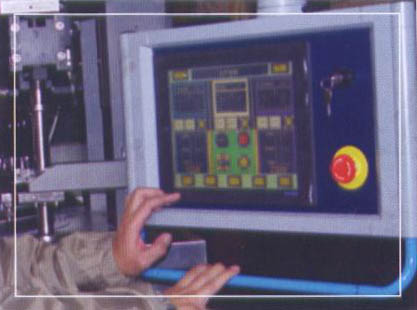

with large color touch screen control system and separate electrical

control panel.

It could be used to produce round,

double-sided engraved or irregular tablets in a wide variety of shapes.

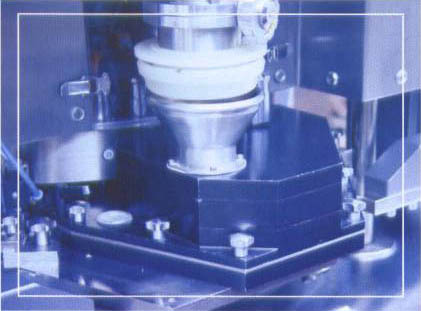

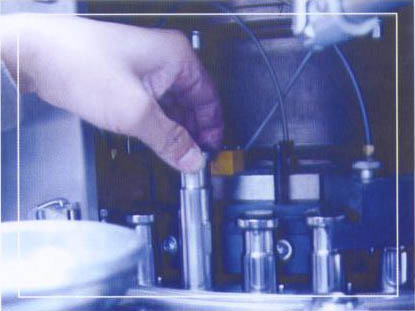

Custom 2~4 punch heads tooling

design available in accordance with

customers special requirements.

Main Features:

* High-Speed, Mass

Production, Bi-Layer, Single-Layer, Double-Sided Tablet Presses

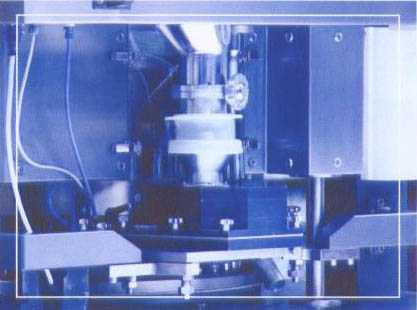

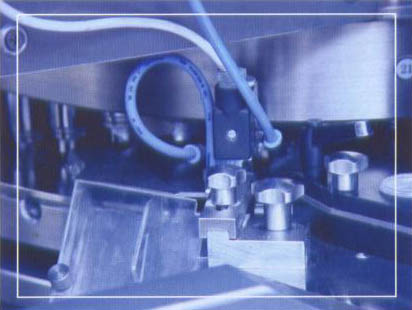

* Pre-Compression

and Main Compression

* Computerized

PLC Control System

* High-Speed,

Precision Tablet Weight Control System

* Automatic Single

Tablet Rejection System

* Extra Large

Mitsubishi Color

Touch Screen Panel

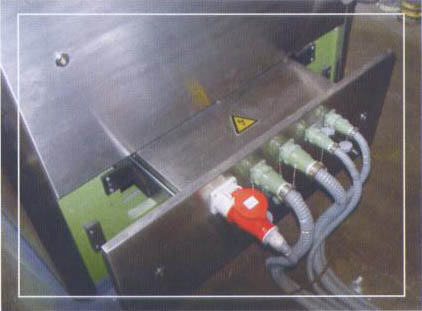

* Separate Electric

Control Panel

* Mechanically and

Electrically Controlled Compression without hydraulics or pneumatics with

SIEMENS and

MITSUBISHI

Electrical Components

* Triple Chamber

Force Feeder featuring easy loading and unloading

* cGMP Standard

* Includes Complete Set

of Filling Cams