|

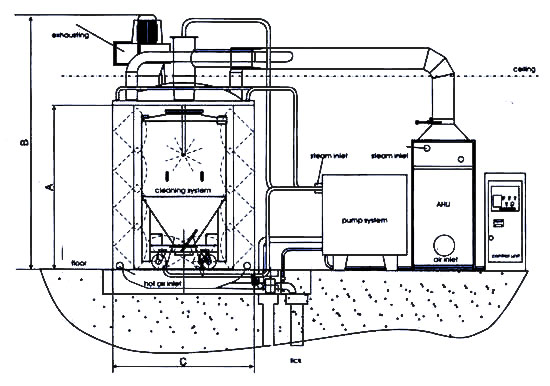

Pharma Lifter Washing Station |

|

VMD series Automatic Washing Station is mainly used in pharmaceutical industry for cleaning the containers as bins, intermediate bulk containers. Its widely used in such areas as pharmaceutical industry, chemical industry, and foodstuff industry. Its made of Austenitic stainless steel. Angles are cambered. There is no dead angle, no concave/convex face and no screws on the surface. Applying the PLC control system, all parameters can be assigned in advanced according to requirements. Using VMD series Automatic Washing Station to clean VLD series Pharma bins or VCD series Intermediate Bulk containers, has optimized producing flow and improved working efficiency. |

| Parameters \ Type | VMD - 600 | VMD - 800 | VMD - 1000 | VMD - 1200 | VMD - 1500 | VMD - 1800 | VMD - 2000 |

| A | 1400 |

1600 | 1650 | 1800 | 1900 | 2000 | 2300 |

| B | 2700 | 2900 | 2950 | 3100 | 3200 | 3300 | 3600 |

| C | 1800 | 1800 | 2000 | 2000 | 2000 | 2000 | 2000 |