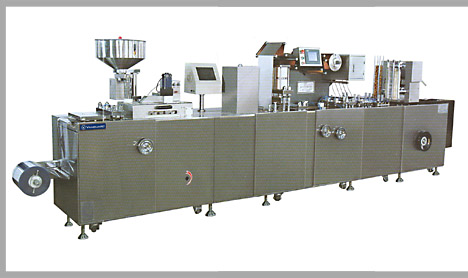

Blister Packing Line

|

Model PBM-250C is a mid speed production blister packing machine designed to pack all types of capsules, tablets, softgels, injection solution, syringe and other small laboratory or hospital preparation products. It can also pack small products in different types of clamp shell packages. It is widely used in the pharmaceutical, herbal, food and other related industries. It is suitable for packing with aluminum/PVC, paper/plastic laminated materials.

Its functions are aluminum foil automatic feeding, upper and lower cobweb male and female joining, multistage cylinder heat sealing, automatic indenting, batch number printing and aluminum alloy double heating. Other new features are as follows: |

| Cutting frequency | 20 - 40 times a minute |

| Output capacity | Up to 7200 blister packs per hour |

| Max shaping area | 240(9'') x 110(4'') mm |

| Stroke (mm) | 40 - 120 |

| Standard sheet (mm) | 80 x 57 |

| Air pressure | 0.4MPa - 0.6MPa |

| Power | 1.5 kw |

| PVC hard pieces (mm) | 0.15 - 0.5 x 250 |

| PTP Aluminum foil (mm) | 0.02 - 0.35 x 250 |

| Dialysis paper (mm) | 50 - 100g x 250 |

| Mould cooling | Running water or back water |

| Dimensions (mm) | 2700(106'') x 890(35'') x 1450(57'') |

| Weight | 1300kg (2866lbs) |