|

Capsule Filling Capsule Polisher

Capsule Sorter

|

| General Description | |||||

| Model VAF-2000E High Speed Automatic Capsule Fillers provide precision dosing of

granules, powders, micro-tablets or pellets into hard gelatin or vegetable

capsules. They are based on the Model VAF-2000C with new technological

advantages such as ultra efficient gear drives, Print-On-Demand, fully

enclosed dosing stations and rotating table, high efficiency and energy saving

are among standard options of our capsule fillers. Each unit is equipped with SIEMENS HMI (Human Machine Interface) and 10.5-Inch Color SIEMENS Touch Screen Control Panel. Highest (99%) acceptable rate of empty gelatin

capsules regardless of suppliers. Suitable for various capsule sizes from 00 ~

4. |

|||||

| More Pictures |

|||||

| Simple maintenance and effortless adjustments, high quality

electronic components and mechanical driven, quick capsule size changeover,

increases the standard of production environment and makes it easier for the

operator to clean after each production batch. It also has a new patent pole elevator unit for raising the dosing stations for easy part changing and cleaning. Each model comes with one set of capsule size change parts, a dust collector unit, and a German vane pump. Our Encapsulators meet international current cGMP Standard with ISO 9001 Certified Manufacturing Facilities. |

|||||

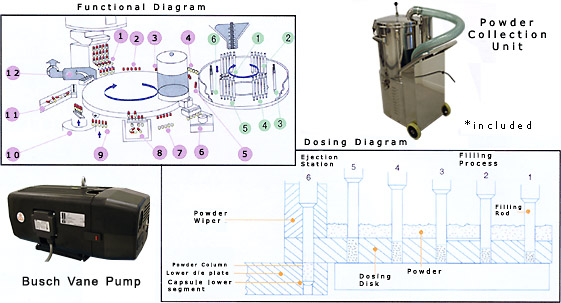

| Dosing Filling Process: | Functional Process: | ||||

| 1. The powder column is compressed to be 1/5 thickness of dosing disk. 2. The powder column is compressed to be 2/5 thickness of dosing disk. 3. The powder column is compressed to be 3/5 thickness of dosing disk. 4. The powder column is compressed to be 4/5 thickness of dosing disk. 5. The powder column is compressed to be same as the thickness of dosing disk. 6. Eject the compressed powder column of proper dosage to capsule. |

1. The capsules are fed to the segments in sequence, the cap and body are

separated by means of a vacuum suction. 2. Transporting 3. Cap and body start to separate 4. Cap and body are separated and prepared for filling. 5. Powder column filling 6. Optional pellet and tablet filling 7. Transporting 8. Eject the faulty capsules 9. Joining of capsule body and cap 10. Capsule body and cap locking 11. Eject finished product 12. Clean the segments |

||||

|