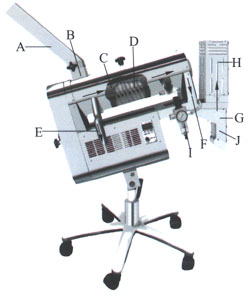

Capsule Polisher and Sorter

Special Features:

- Newly designed to polish

capsules and tablets as well as to eliminate static.

- Automatic reject ultra light

weight capsules, loose pieces, and empty capsules.

- Hook-up directly into

any automatic capsule filling machine or tablet press.

Comparing to Traditional Capsule Polishers:

Old Type Polishers:

- Cannot hook-up to the

capsule filling machines or tablet presses to have products polishes

immediately after production.

- Cannot reject low

weight, loose pieces and empty capsules.

- Soft cylinder net can

easily jam the capsules.

- The printed letters or

logos on capsules are easily being destroyed.

- Hand-made brush is

difficult to change and the brush hair can come off.

- Difficult to clean and

maintain.

- The DC motor makes the

carbon brush wear out easily.

Our New Polishers:

- The height and angle can

be adjusted to fit into any chute of the capsule filling machines

and tablet presses.

- Automatically reject low

weight, fragmented, and empty capsules.

- New type net cylinder

ensures no jammed capsules during operations.

- The capsules are not

directly contacted with the metal net to protect the printed

capsules effectively.

- Our new type of brush is

easy to change and it is durable.

- Excellent design for

quick cleaning and maintaining.

- The three phase motor is

controlled by a frequency converter, which is great for continuous

long hours of operations.

-

Each Unit comes with 1

extra brush!

|

Model

|

PCX-III

|

PCX-IV

|

|

Capacity

|

150000 capsules/hr

|

300000 capsules/hr

|

|

200000 tablets/hr

|

400000 tablets/hr

|

|

Power

|

AC110/220V, 50/60Hz 2A

|

|

Dimension

|

37 x 24 x 39

|

45 x 24 x 39

|

|

Weight

|

35 kg (77 lbs)

|

40 kg (88 lbs)

|

|

Vacuum

|

2.7m3/min

-0.014MPa

|

|

Compressed

Air

|

0.25m3/min

0.3MPa

|

|

|

Working

Principles:

- From the capsule filling

machine, the finished capsules are fed into chute A.

- The turning brush rotates

the capsules from the B to C cylinder.

- Within the net cylinder,

brush D polishes and dedusts the capsules; the loose pieces and empty

capsules are retrieved by a vacuum suction E.

- The brush conveys the

capsules to the outlet of cylinder F.

- In the sorter segment G

clean compressed air collects low weight capsules, loose pieces and

empty capsules to H collector.

- The pressure of the

compressed air is shown on the filter decompressed valve meter, which

can be adjusted at different requirements.

- The qualified capsules are

ejected from outlet J.

|