|

General Description

Our mid-speed capsule fillers designed to fill hard gelatin capsules with powder, pellets

or granular materials.

It is durable and reliable encapsulators that fill dosages to the highest accuracy. The operation is very smooth, low noise, simple to operate,

and easy to maintain and clean.

These machines

are built to meet the worlds most advanced encapsulating production requirements. All parts are made of high quality stainless steel to meet the cGMP Standard.

We integrated only SIEMENS electrical components and SIEMENS PLC for

reliability.

The filling dosage can be adjusted and the powder can be filled according to the volume requirements.

All encapsulators come

with one set of capsule sized changeable parts, a dust collection

unit, powder recovery unit, BUSCH Dry Pump, a built-in air compressor unit and a water cooling

system.

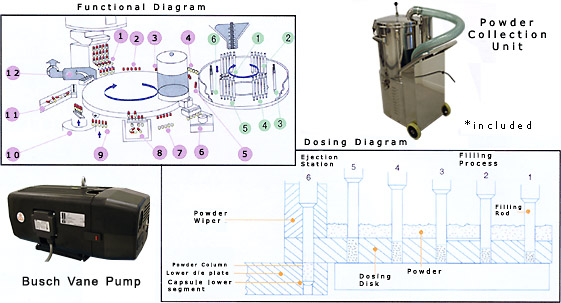

Dosing Filling Process:

1. The powder column is compressed to be 1/5 thickness of dosing disk.

2. The powder column is compressed to be 2/5 thickness of dosing disk.

3. The powder column is compressed to be 3/5 thickness of dosing disk.

4. The powder column is compressed to be 4/5 thickness of dosing disk.

5. The powder column is compressed to be same as the thickness of dosing disk.

6. Fill the compressed powder column of proper dosage into capsules.

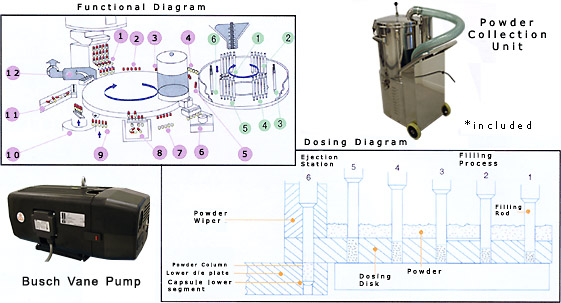

Functional Process:

1. The capsules are fed to the segments in sequence, the cap and body are separated by means of a vacuum suction.

2. Transporting

3. Cap and body are separated and prepared for filling.

4. Powder column filling

5. Optional pellet and tablet filling

6. Eject the faulty capsules

7. Transporting

8. Joining

of capsule body and cap

9. Eject finished product

10. Clean the segments.

|