|

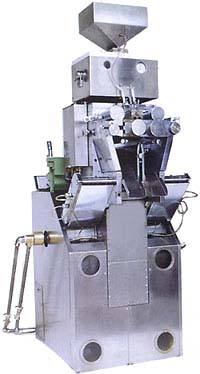

The Model VSG-172A Softgel Manufacturing Line is an advanced design rotary die encapsulator with the cooperation of injector, water cooling system, spreading chamber and die to form all kinds of oil and liquid into variety form soft capsules. It is widely and popular used worldwide in the pharmaceutical, nutraceutical, herbal, food and cosmetics fields. It is applicable to filling all substances, which cannot be melted in water.

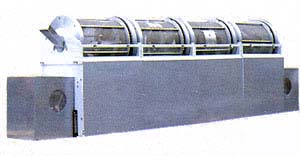

The overall soft gelatin capsule process starts from the gelatin that is melted and de-bubbles via the gelatin tank, then mixing the formula and color. Through the encapsulation machine, the melted gelatin solidify to the gelatin ribbon which the material solutions are filled and sealed; then cutting and forming into soft gelatin capsules. Finally, the softgels are to be dried, inspected and packed accordingly.

It is a fully automatic softgel encapsulator line with features as follows:

- High production capacity

- Stepless control encapsulation

- Universal construction for a more simple maintenance

- Easy to operate and clean

- Gelatin ribbon making, filling and sealing

operation can be accomplished on the main machine

- All parts and components contacted with materials are made of high quality stainless steel or chrome plate to meet the GMP Standard.

- High quality and Efficient Operation

- Set-up, Installations, Training and Support in making sample batch products are available upon request.

|