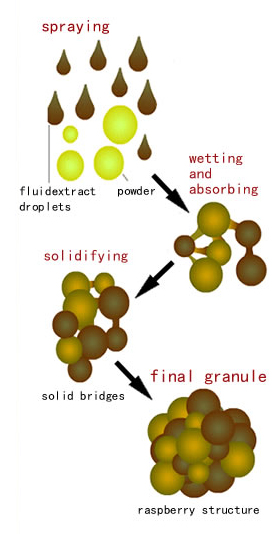

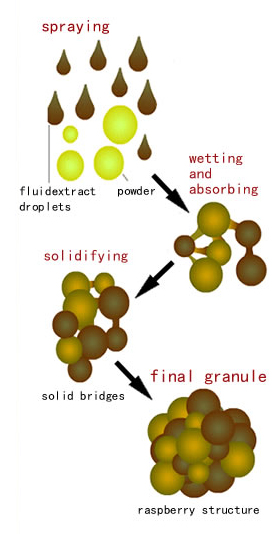

The agglomeration process has been developed as a

solidifying process for liquids. A (or more) powdery adsorbent (for example:

sugar, starch) is used as a carrier and saturated by the liquid. The final

granules integrate spray-dry components from the liquid and the carrier powder.

Because a considerable volume of liquid must be evaporated, the drying

efficiency of the processor should be high. Vanguard recommends two series fluid

beds VFL and VPL for this process.

VFL and VPL have been

successfully applied to make the granules of all types of natural herbs and

herbal formulas. It is even great for making granules with more than ten different

herbs in a single formula. The

herbal fluid extracts are viscous and difficult to be dried. Comparing with the

traditional wet-granulation process, the high efficient and potent of VFL and

VPL processes save energy, time and reduce the quantity of the excipient significantly.

|

|

Agglomeration is the

first technologic innovation developed from the original fluid bed dryer.

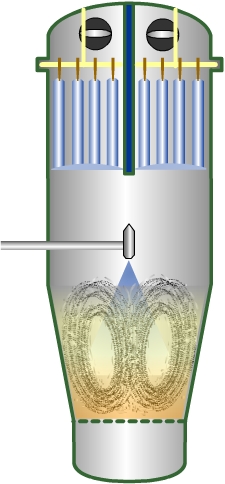

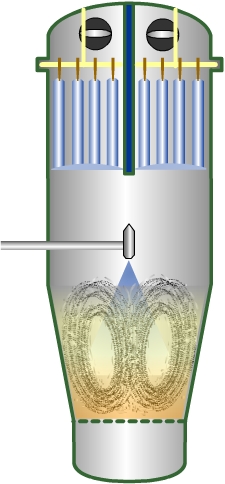

Vanguard offers two types top spray systems - VPL and VFL. The powder is

charged in the container of the fluid bed and fluidized by the hot air. The

binding liquid such as solution, suspension is sprayed on the fluidized powder

to build liquid bridges among them. The liquid bridges are dried by the hot

fluid air to stick the powder together. While the liquid sprayed continuously,

the particles grow bigger to a desire grain size.

Product

characters

|